Prime Compressor

Oil-Free Nitrogen Compressor Systems

High-pressure N2 compression solutions designed for reliability, efficiency, and contamination-free operation in continuous industrial processes

Prime Compressors are ideal for nitrogen compression. Thanks to their oil-free and flexible design, they can fulfil various requirements and applications across diverse industries. Our nitrogen compression solutions deliver reliable, contamination-free performance for any N2 application.

Our oil-free nitrogen compressors deliver pure, contamination-free N2 compression for critical industrial applications. Engineered with flexible, modular design, these systems adapt seamlessly to diverse pressure requirements and operational demands—from pharmaceutical manufacturing to high-pressure cylinder filling.

The completely oil-free technology ensures your nitrogen remains 100% pure throughout the compression process, meeting the strictest industry standards for food-grade, medical-grade, and industrial-grade applications. Robust construction enables continuous operation, while intelligent design maximizes energy efficiency and minimizes maintenance requirements.

Ideal for:

Oil-free nitrogen compression systems for backup gas supply behind generators, ensuring reliable storage in pressurised containers for uninterrupted industrial operations.

High-pressure nitrogen compression solutions for filling gas cylinders up to 300 bar, delivering consistent performance for commercial bottling and cylinder filling stations.

Dry-running piston compressors engineered for nitrogen recompression in extreme offshore environments, providing reliable operation under harsh marine conditions.

Specialized nitrogen compression for protective gases used in vulcanisation processes during automotive tire manufacturing, ensuring optimal production quality and safety.

Oil and silicone-free compression technology for process and instrument air applications, delivering ultra-pure nitrogen for sensitive system components and analytical equipment.

Dry-running nitrogen compression systems for sealing and packaging foodstuffs with protective gases, maintaining product freshness and extending shelf life in Modified Atmosphere Packaging (MAP) applications.

Our oil-free and durable N₂ compressors guarantee contamination-free nitrogen processing, even in continuous operation.

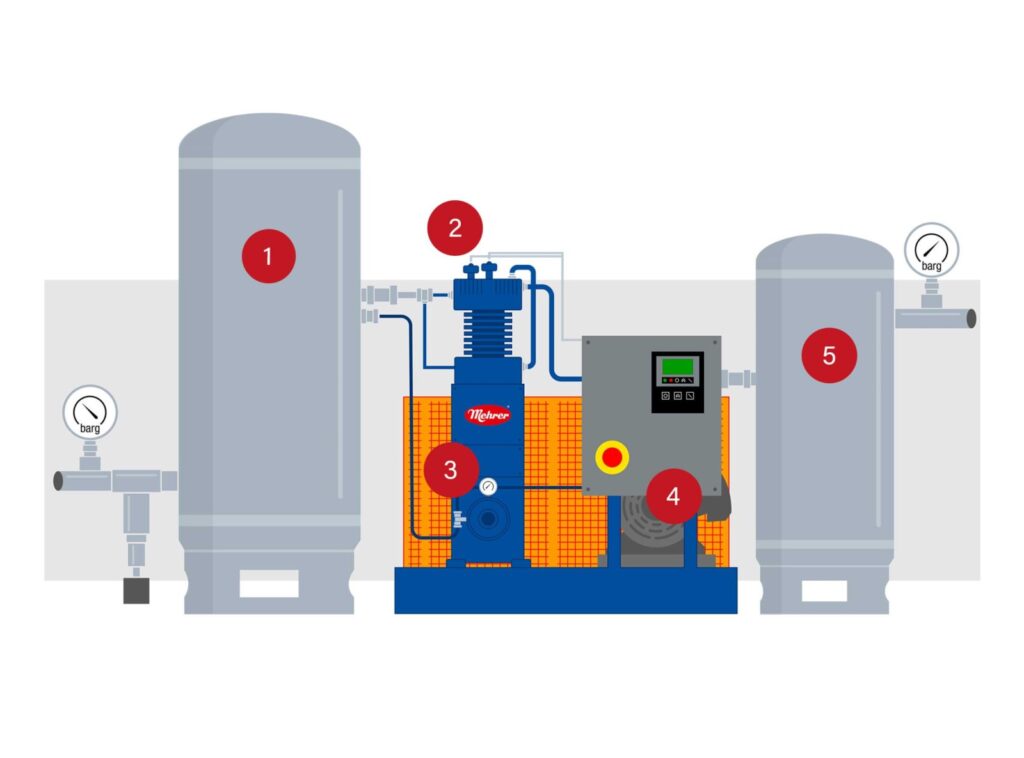

1 | Pressure vessel – Buffer tank on the suction side

2 | Valve lift-off – Precise control of the nitrogen compressor

3 | Nitrogen booster – Oil-free after-compressor for maximum efficiency

4 | Control panel – Integrated control for the compressor unit

5 | Pressure vessel – Buffer tank on the pressure side