Prime Compressor

Hydrogen Compressor Solutions for Clean Energy

Discover high-pressure, oil-free compressors for green hydrogen applications. Leading technology for safety, durability, and flexible modular design.

Prime Compressor’s high-pressure hydrogen compressors deliver advanced solutions for efficient H2 compression. Our customizable system designs support projects with variable intake pressures and ultra-high final pressures—up to 1,000 bar. With oil-free and modular technology, we ensure maximum safety, reliability, and flexibility for hydrogen refueling, storage, and industrial applications.

Prime Compressor’s high-pressure hydrogen compressors are engineered for safe and efficient filling of gas cylinders and trailers. With robust oil-free technology and modular design, our compressors handle variable intake pressures, supporting large-scale hydrogen transportation and storage. Suitable for hydrogen refueling stations and distribution networks.

Our advanced hydrogen compressor systems are perfect for the compression of hydrogen-containing gas mixtures, such as synthesis gas. With flexible capacity and stainless steel components, Prime Compressor guarantees energy-efficient operation for chemical and industrial hydrogen synthesis applications.

Secure and reliable compression of dry or saturated hydrogen after electrolysis is essential for green hydrogen storage solutions. Prime Compressor’s high-pressure, oil-free hydrogen compressors maximize energy density, enabling safe long-term storage for power-to-gas and renewable energy projects.

Prime Compressor supports catalytic reforming processes with advanced oil-free hydrogen compressors. Our systems allow safe hydrogen recycling, ensuring H2 purity and minimizing emissions in industrial production, including steel manufacturing and energy recovery applications.

For large-scale energy projects, Prime Compressor’s technology enables feeding regeneratively produced hydrogen into natural gas grids. Our compressors ensure safe, controlled, and energy-efficient gas injection for grid balancing, decarbonization, and sustainable power supply.

Prime Compressor high-pressure compressors are the key solution for compressing hydrogen to produce synthetic fuels (e-fuels). Integrate our systems into power-to-liquid processes for maximum efficiency, safety, and return-on-investment in future-oriented green energy industries.

Hydrogen represents the next step toward climate-friendly energy, providing a sustainable alternative to fossil fuels. Whether used for refueling fuel cell vehicles, producing synthetic fuels, injecting into natural gas grids, or supporting steel production, hydrogen delivers powerful solutions for decarbonizing industry. Prime Compressor’s high-pressure hydrogen compressors play a vital role—compressing hydrogen post-electrolysis to pressures up to 1,000 bar. This technology boosts energy density and enables secure, efficient storage for a greener future with reduced CO₂ emissions.

With Prime Compressor’s oil-free and wear-free hydrogen compressors, green hydrogen produced from renewable sources can be stored efficiently and safely. Our innovative technology maximizes energy density while ensuring system longevity, low maintenance, and unmatched reliability for sustainable energy projects.

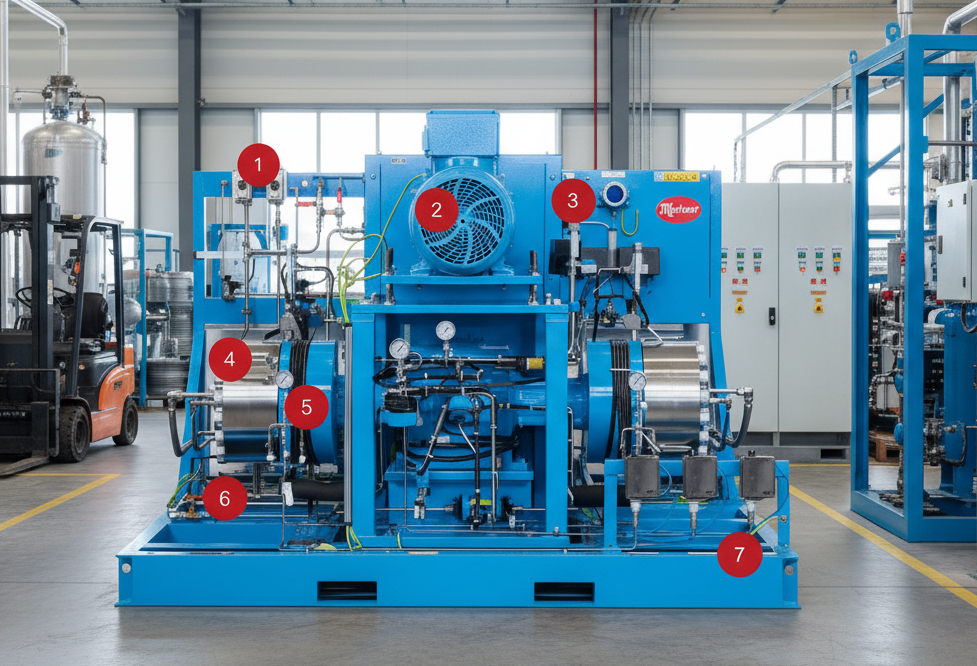

1 | Pneumatic shut-off valves – Safely integrated into hydrogen systems

2 | Drive motor – Designed for frequency converter operation for flexible volume flow control

3 | Signal transmitter – In Ex version for potentially explosive atmospheres

4 | Gas train – Made entirely of stainless steel for maximum durability

5 | Cylinder heads – Made of stainless steel for a long service life

6 | Heat exchanger – Water-cooled stainless steel heat exchanger for efficient recooling

7 | Base frame – Vibration-isolated or permanently mountable